NDT Training Courses from Jan-Jun 2025

Technical Inspection and Verification Co., Ltd. (TIV), an expert in Non-Destructive Testing (NDT), has announced its NDT training courses for the first half of 2025, covering a wide range of techniques to meet the needs of personnel in the industrial sector.

Why Learn NDT?

Non-destructive testing (NDT) is an important technique used in a wide variety of industries. It is used to assess the quality and integrity of materials or parts without destroying or damaging them. It helps to detect flaws, cracks, and other abnormalities that may affect the strength, performance and safety of a structure or equipment.

NDT plays an important role in various industries, such as:

- Oil and Gas Industry: Inspect pipelines, storage tanks and equipment to prevent leaks and accidents.

- Petrochemical Industry: Inspect piping systems, pressure vessels and other equipment in plants.

- Energy Industry: Inspect power plants, turbines, boilers and piping systems.

- Aviation and Aerospace Industry: Inspect aircraft, aircraft parts and spacecraft.

- Automotive Industry: Inspect car parts, body structures and systems.

- Construction Industry: Inspect building structures, bridges and various structures.

Learning NDT helps to:

- Increase job opportunities: NDT specialists are in demand in the labor market.

- Develop potential: Enhance knowledge and skills for career advancement.

- Certify standards: Obtaining a certificate demonstrates ability and expertise.

Training courses offered include:

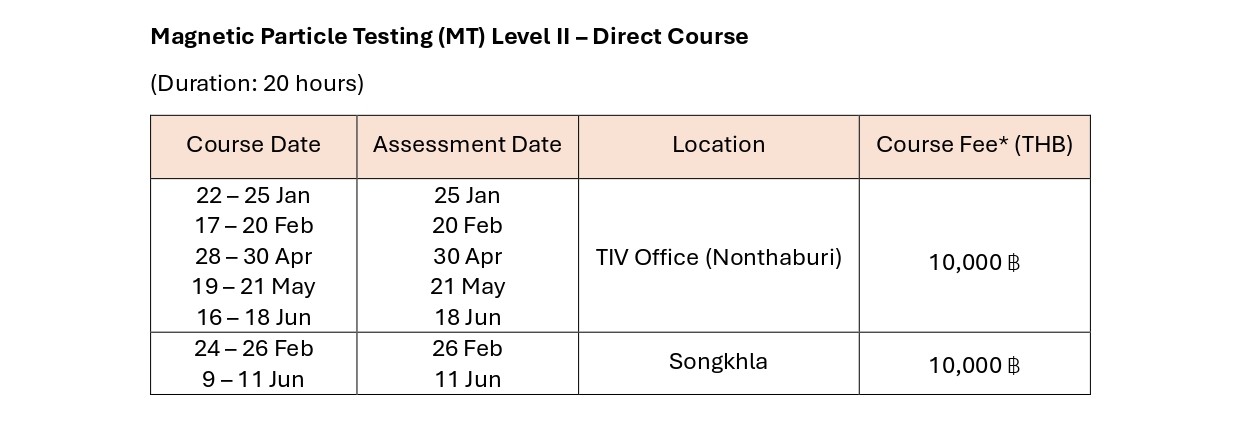

- MT (Magnetic Particle Testing): This technique is used to detect defects on and below the surface of ferromagnetic materials such as iron, nickel and cobalt. It uses the principle of magnetic fields and magnetic powder to indicate the location of cracks or defects.

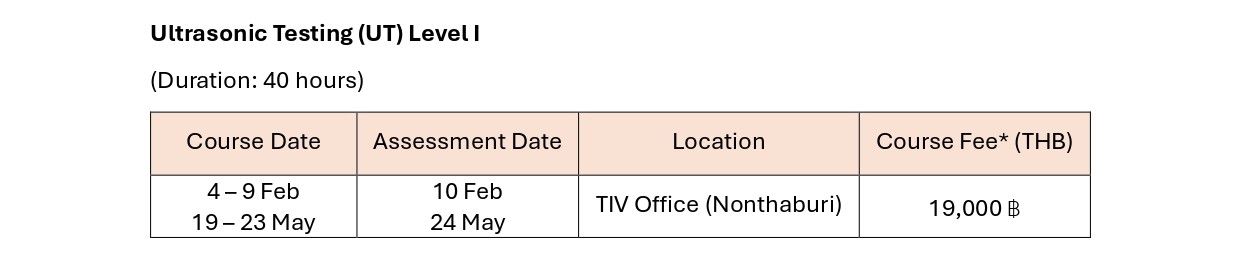

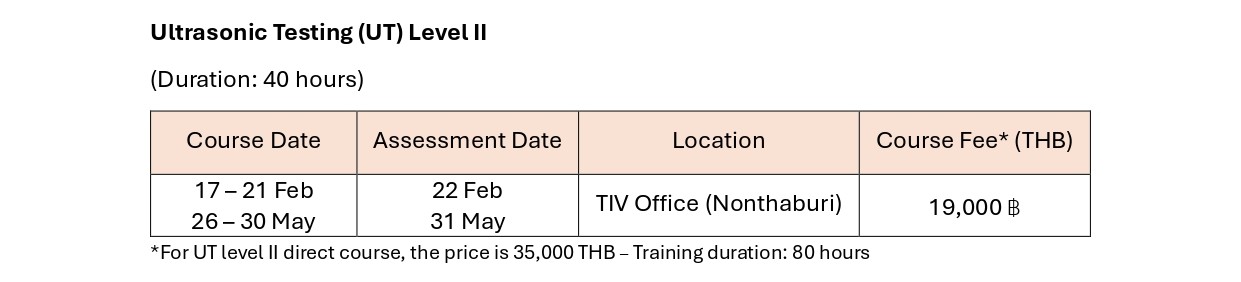

- UT (Ultrasonic Testing): This technique uses high-frequency sound waves to detect defects within a material. It uses the principle of sound wave reflection that passes through the material, and analyzes the pattern of reflected waves to identify the location, size and nature of the defect.

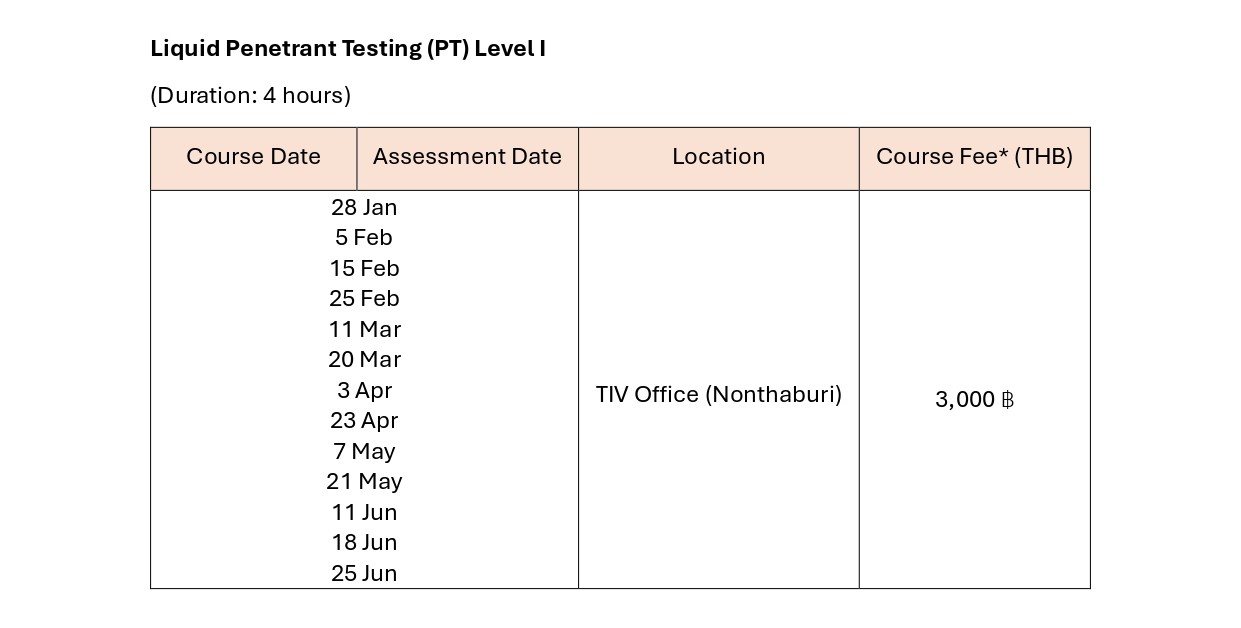

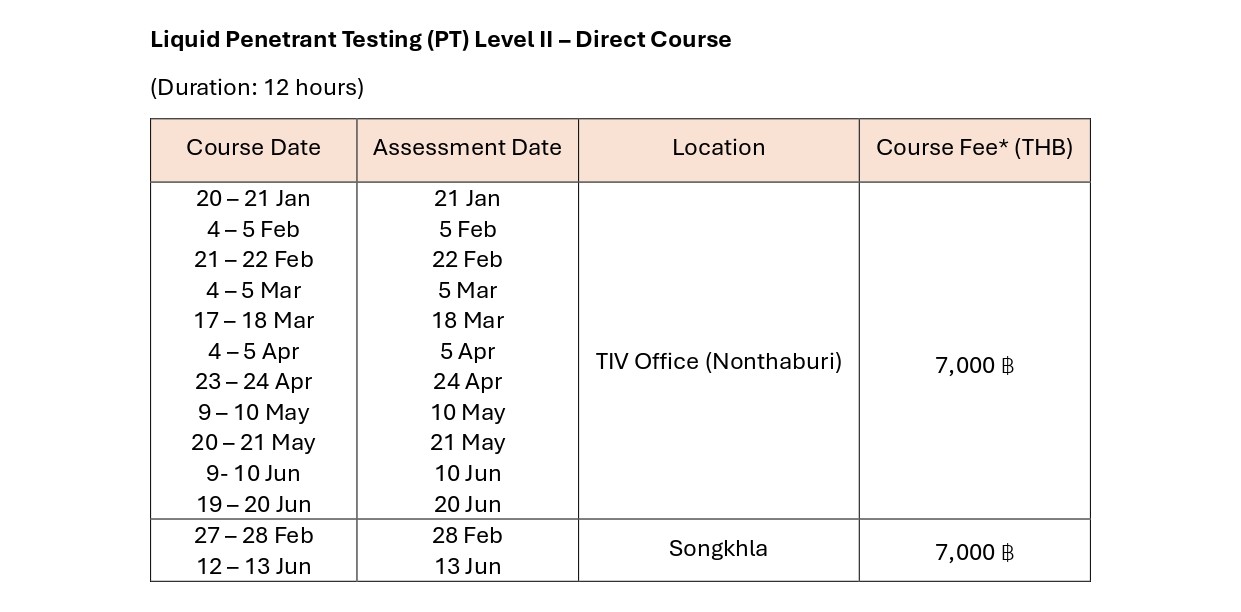

- PT (Penetrant Testing): This technique is used to detect defects on the surface of non-porous materials. It uses the principle of a penetrant that can seep into cracks or pores on the surface of the material, then uses a color developer to indicate the location of the defect.

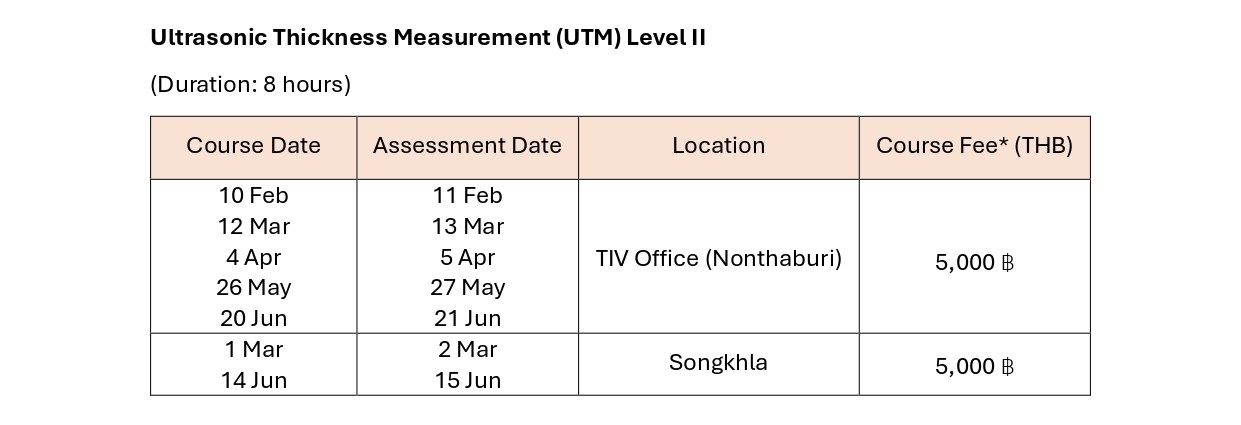

- UTM (Ultrasonic Thickness Measurement): This technique is used to measure the thickness of a material using the principle of sound waves that pass through the material, and measures the time the sound waves travel back to calculate the thickness of the material.

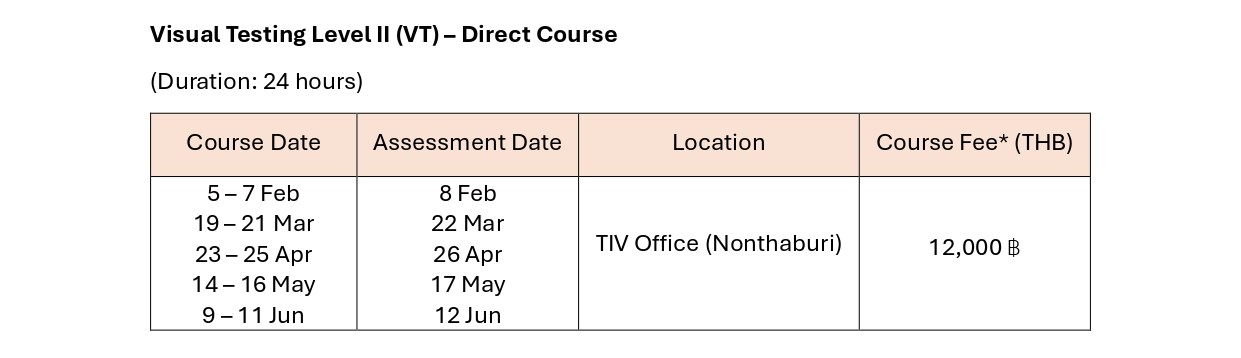

- VT (Visual Testing): This is a basic technique used to detect defects on the surface of a material by observing with the naked eye or using aids such as microscopes or binoculars.

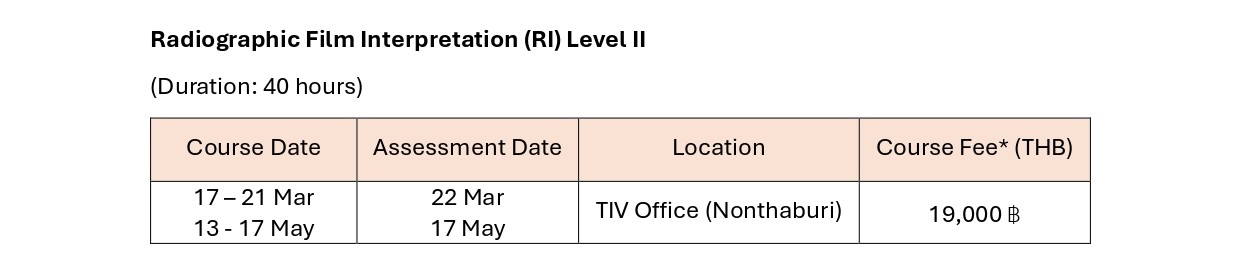

- RT (Radiographic Testing): This technique is used to detect defects inside a material by passing radiation, such as X-rays or gamma rays, through the material and recording it on film or a detector to display images and analyze for internal defects.

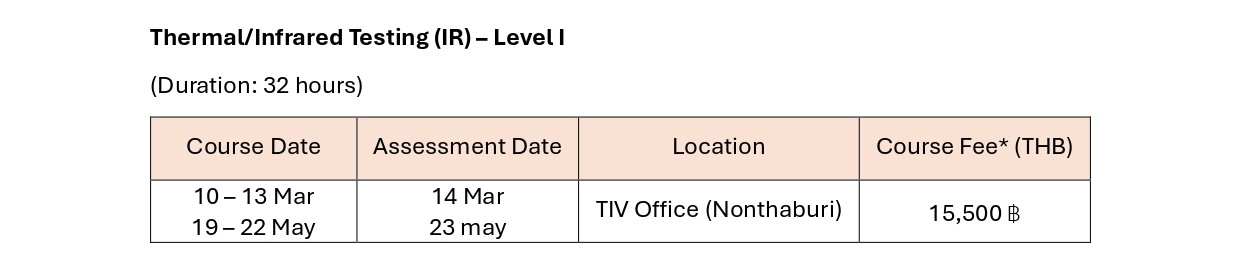

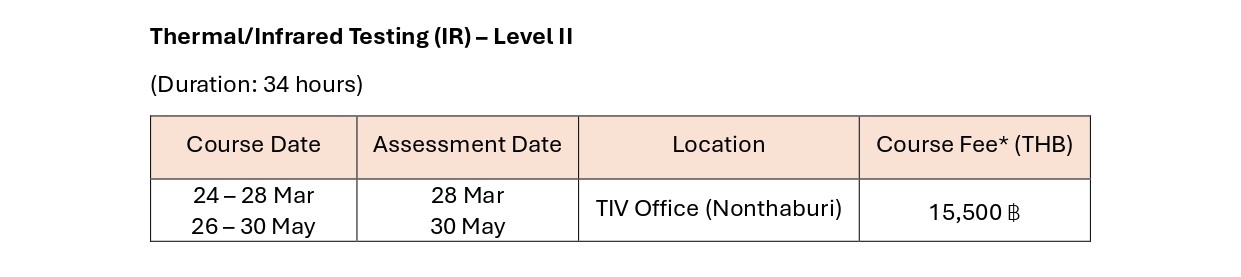

- IR (Infrared Thermography): This technique is used to detect abnormalities in temperature on the surface of a material using the principle of infrared radiation emitted from the material. It uses a thermal imaging camera to display images and analyze the temperature distribution.

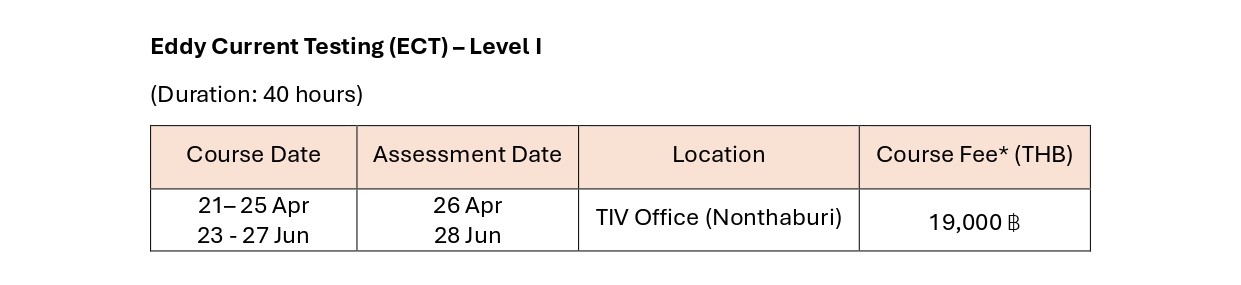

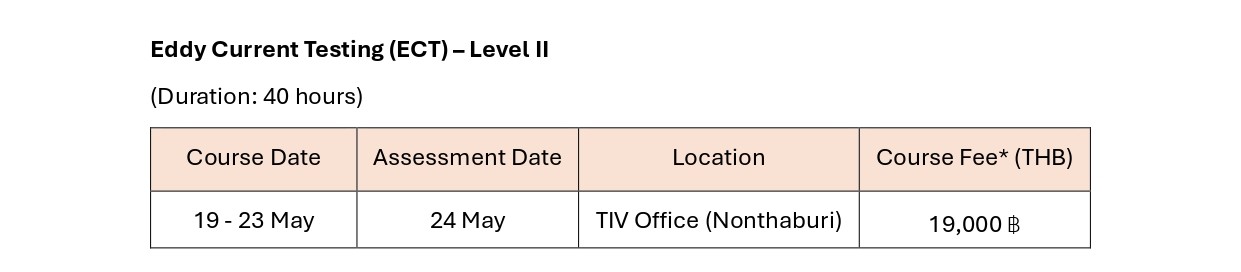

- ECT (Eddy Current Testing): This technique is used to detect defects on and below the surface of conductive materials such as aluminum and copper by using the principle of electromagnetic fields and eddy currents that occur in the material to detect changes caused by defects.

NDT Training Schedule Jan-Jun 2025

Non-Destructive Testing (NDT) – SNT-TC-1A (2024)

Note:

- The above prices do not include 7% VAT.

- The course will be opened when there are at least 4 applicants.

- Seat reservations will be considered on a first-come, first-served basis.

- Registration will be confirmed upon full payment.

- Payment can only be made via bank transfer or check.

- Full refund if TIV cancels the course due to force majeure.

- TIV reserves the right to cancel, change schedules, modify course content, or fee structure as appropriate.

- Applicants must meet the qualifications specified in ASNT SNT-TC-1A.

Certification Criteria:

- Attend no less than 80% of the total class time.

- Pass the General, Specific exams with no less than 70% and the Practical exam with no less than 80%.

- The combined score of General, Specific and Practical must be no less than 80%.

- Pass the eye test (Jaeger No.2 near vision acuity and color blind).

- Retake exams are possible within 1 month after the first exam with an additional fee of 800 baht per subject.

To apply for training or inquire for more information:

Email: info@tiv.co.th

Tel: +66 2 002 0225/+66 99 712 8840

37 Rattanathibet Rd, Bang Krasor, Mueang Nonthaburi District, Nonthaburi 11000